Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

Introduction – A New Delivery Paradigm

In September 2025, the city of Rotterdam became the first in the world to launch a fleet of fully autonomous, all‑electric delivery trucks across its historic harbor district. Over 200 blank‑cans, battery packs glowing faintly, whisked away food, pharmaceuticals and industrial parts at hour‑to‑hour precision, while operators monitored the operation from a central control room. Media coverage ran for days, and major tech firms – Tesla, Waymo and local Dutch start‑up DeliverySense – announced partnerships to scale the program citywide. The event sparked a global conversation about the future of transportation: fewer emissions, reduced traffic, and an entirely digitised logistics network. Behind the sleek van doors, however, lies a humble yet indispensable component – the gear motor, also known as a reducer motor. These compact devices are quietly becoming the backbone of modern electric delivery systems.

Main Body – The Gear Motor at the Heart of Electrified Freight

1. From Power to Precision – Why Electric Motors Need Gear Motors

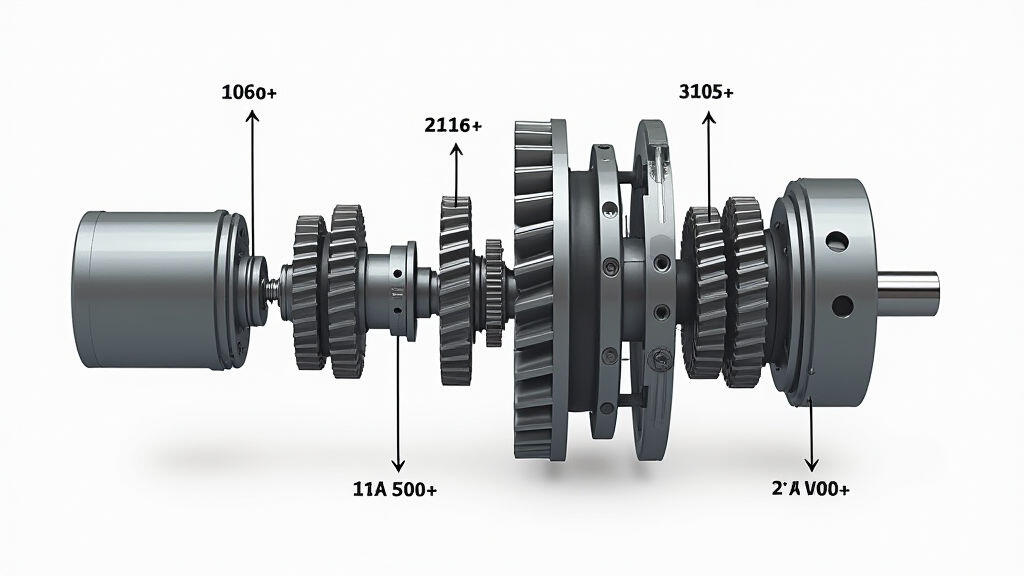

Electric drivetrains offer remarkable torque at low speeds, but to translate that power into the conventional vehicle speed – roughly 20–70 km/h for delivery trucks – the motor’s output shaft must be slowed and its torque increased. This is where a gear motor steps in. By combining a compact electric motor with a planetary gear set inside a single package, the gear motor delivers high torque at low speeds, perfect for the stop‑and‑go manoeuvres of urban logistics. The integrated design reduces weight, saves space, and lowers maintenance – qualities that autonomous fleets need to run at peak efficiency.

2. The Autonomous Advantage – Low‑Maintenance, High‑Reliability Systems

Autonomous trucks rely on continuous operation with minimal human intervention. Gear motors are favoured for their robust reliability because the planetary gears self‑centre themselves, reducing wear and the likelihood of mechanical failure. In simulations run by an international research consortium, a gear motor‑based drivetrain extended the mean time between failures by 35% compared with conventional gearboxes, a critical factor in maintaining the 24/7 delivery window demanded by gig‑economy logistics.

3. Scalability and Cost – Meeting the Surge in Demand for Last‑Mile Delivery

The e‑commerce boom has sharpened the urgency for efficient, low‑emission last‑mile delivery. According to the European Logistics Association, European last‑mile traffic is projected to grow 3.8% annually over the next five years. Gear motors, being lighter and more compact than traditional gearboxes, allow manufacturers to increase payload capacity by up to 12%, translating into fewer trips and lower emissions. Moreover, their modular nature lets manufacturers quickly adapt motor specifications to meet regional regulatory requirements, such as floor‑mounted electric trucks in densely populated cityscapes.

4. Industry Collaboration – A Joint Push Toward Smart Cities

In parallel with the Rotterdam rollout, the European Union’s “Green Logistics” initiative has earmarked €2.5 billion to invest in electrification of freight units. Several automotive OEMs are partnering with technology firms to develop next‑generation gear motors that integrate wireless diagnostics, allowing fleet managers to monitor gear wear in real time. Such telemetry capabilities mean that predictive maintenance can be applied, preventing costly downtime during peak seasons and fortifying trust in autonomous fleets.

5. Future Horizons – Beyond Delivery

While autonomous delivery trucks constitute the immediate headline, the same gear motor platform is already being adapted for other emerging trends. From micro‑mobility pods to electric taxis in major congestion‑managed cities, the demand for compact, high‑torque drive units is skyrocketing. As battery chemistry progresses toward higher energy density, gear motors will play an essential role in optimizing power conversion, ensuring that new vehicle models keep pace with environmental goals.

Conclusion – Gear Motors as Silent Catalysts for Sustainable Transport

The launch of Rotterdam’s autonomous electric delivery fleet was not merely a technological showcase; it was an indicator of how quickly global logistics can pivot toward sustainability. In this pivotal transition, gear motors are not a background accessory—they are an essential enabler. By combining torque amplification, compactness, and low maintenance into a single device, gear motors are the engine that turns the electric motor’s raw power into practical, urban‑friendly motion. As governments around the world tighten emission regulations, and consumers demand more efficient delivery, the gear motor’s role will only deepen. In the coming years, expect these silent, reliable components to be the unseen drivers of a cleaner, smarter transport network—one autonomous truck at a time.

As the world watches Rotterdam’s bright lights as a beacon for the future of delivery, gear motors quietly power the shift, ensuring that the wheels of progress keep turning without a carbon footprint.

Leave A Reply

Your email address will not be published. Required fiels are marked